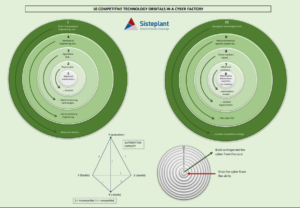

It is an strategic sofware piece for the cyber factory. Traditional MES are more operative systems filling the gap between the MRP-2 and the real-time that imperates in the shop floor, but the fact of having in Captor embebbed-friendly intelligent algorithms convert it in something valuable difference. Here’s why.

The sense of the cyber factory is not only advanced flexible automation and its main cast the robotics, but the intention of having permanently under real-time control by humans its intrinsinc natural concurrent events as well.

These events range from horrizontal and vertical SPC warnings and predictive machine and process reliability to flexible flow optimization and lead-times alarms.

The think is not to pretend a model in wich the computer decides what to do using the A.I. and traditional advanced algorithms that Captor manages. This, through complex enough to the programmed, is not useful by itself, because would represent only tactical actions.

What means that? Single tactical actions lack the intelligence of strategical high-level mind decissions only qualified humans can have. So, the challenge that Captor® – Prisma® has solved is to give people the filtered capacity to concurrently interact with the low optimized level decissions presented by it’s A.I. models, calculus that humans can’t compute with precission nor the agility of the real time, as well as the criss-cross complications of integral alarms over process, maintenance and flows.

The advantage of that is confidence and acceptance by engineers and plant operators, as well as (very crucial) the capacity of the Captor®-Prisma® models to train people in the roots of process and reliability variations.

So the expectations of an I-MES like Captor® over other plane MES systems is that in a correct implementation:

- Quality improves directly at least 50% more.

- Machine breackdown is directly reduced al least by a 80%.

- Lead times are reduced by at least a 50%.

- Engineers and operators grow in their technical level, putting them in a plane un-reachable by robots.

The implementation steps are so more delicated and important that with traditional MES, but it worths because all of that means a direct pay-back of 1 year or less.