Any new clean energy or greener fuel generation plant need to graze perfection. As a commodity factory dealing with a very sensitive subject, must perform value creation evidence along operation. From solar pads to hydrogen or new advanced nuclear power plants, the commons are:

- Sophisticated equipment

- Full safe automation with adaptive-predictive PIDs

- Continuous running round the clock

- Capital intensive

- Need for an extreme performance and efficiency

- Need for extreme reliability

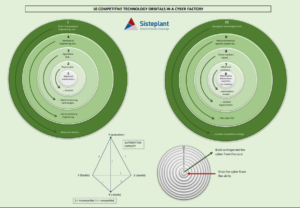

Performance and efficiency are measured by 4 basic inter-dependent elements that must be controlled in real-time:

So we need fix items by design, otherwise no operational practice could improve, and have done it apply very special managerial habits, appropriated for a context in which there’s a very little margin for error and delays.

Note that the loop Q – OEE – C is self dynamic – contained, requiring intelligent precise automation to be real-time balanced, and that overall waste reduction, a symptom of a fine operation procedure, is an “external” force that can improve or deteriorate such balance.

The design conditions that help to make the loop Q – OEE – C stable at a higher throughput level are the following:

- Extreme high quality equipment items

- Robust, rigorous and simple integration design: question each nut and screw!!

- Design for reliability of the loop Q – OEE – C

- Real-time predicitive reliability of Q – OEE – C , this needing the use of A.I. reliability focused software such as Sisteplant’s Promind® and Prisma® (CAMT)

- Process + Maintenance Engineering as an holistic unique block with a given methodology such as TIM (Tech Integrated Maintenance) of Sisteplant

Note again that the last two need a Scientifical Maintenance as the only feasible path of the required holistic integration.

What does it mean Scientifical Maintenance?

- Deep process and equipment physical laws dominion

- Math and A.I. models design and results a knowledge

- Predictive managerial as a daily practice

- Practical approach linking failure in any Q – OEE – C – W with those physical laws, and so working out much more sounded solutions and adjusting the models.

Where and how can Sisteplant help to you in the configuration and exploitation of an advanced facility like these?

- In assessing the coherence and rigorous completion of the Q – OEE – C balanced loop design

- In the definition and implementation of the Scientifical Maintenance Required Model

- In the practical implementation of the intelligent simulation and Maintenance technology management with Promind® and Prisma®

- With the MES software Captor® that controls and links with Prisma and the process PIDs regulators all the plant events not directly related (though relevant) to the process variables evolution

And how?

With a commitment with the setting up of an effective technology driven organizational model much more beyond the mere classical ICT implementation.