Authors:

Ana Borda Zabala, Msc Industrial Engineer, Phd student in SDU, University of Southern Denmark.

Javier Borda Elejabarrieta. Dr. Mechanical Engineer, Msc. Math models, MBA, Yachtmaster Captain, President of Sisteplant, S.L.

THE CONTEXT and INTRODUCTION

Frequently identified as a “classic industry”, this meaning traditional practices and technology, the nature of its operation says just the opposite:

- One of kind complexity

- Enormous design challenges

- Difficult handling of sizes and weights

- Increasingly high tolerances, first time quality

- Shorter delivery times and need for synchronization

- Increasing emission control regulations in the manufacturing process

All of them giving out opportunities to radically improve mainly via lay-out and flow optimization, automation, and ICT integrated advanced application from design to manufacturing to after commissioning service.

This involved complexity may allow shipyards to survive the competence of eastern low-cost countries even with more standard ships, focusing only in the process efficiency and product reliability. Apart from, is the product innovation in advanced and rare crafts, but this last is not sustainable anymore if the manufacturing keeps so manpower intensive and full of non-quality, non-agile pools.

Important so this point, because special advanced ships have reduced market, with hard technical competition to be learned through those who have been doing excellent with simpler ones.

We’ve never seen a shipyard closing if it has set up this strategy, but for business myopia or confidence on public power salvation.

Some big pushers for the X.0 cyber-FoF shipyard coming are the following:

- Aux shops – feeding lines aligned perpendicular along the dry or wet docks (for small repetitive ships, moving the craft along in the dock).

- Avoid crossing flows from the Aux-shops to the dockyard, so minimizing interferences and waits.

- Do as much complete blocks, including conducts and installations, in the Aux-shops, performing “plug & handling & automation” in the dock.

- Fast general – purpose automated handling devices for moving items from the Aux-shops to the ship, perpendicularly to the dockyard axis.

- Gantry cranes travelling the LOA (length overall) of the ship, in a number equal to the Aux-shops feeding lines, approximately the length of the dockyard divide by 50 (in meters). This means that one crane operates ± 25m from its central position.

- When possible, a second different position of the ship along the dock for the final assembly of housing and equipment. Never try to mix both, they have a different nature of handling, the last more frequent and based on purchased items.

- This is easy to be set up with a floodable – dock, obviously, the first position being ready for the next ship order.

- Laser alignment for welding assembly and screwing.

- Light magnetic robots for small assemblies and paintings.

Engineering and Organization

- Integrate compact teams of product and process engineering, the first one general purpose, and others for each Aux-shop line.

- Use a M.E.S. (Manufacturing Execution System) software with compatibility to crisscross real time predictive actions and alarms over engineering, manufacturing, and suppliers. These actions could be over tolerances, lack of specification accomplishments, fault of components, or malfunction.

- Work at the pace of synchronizing “dynamic virtual-cells” that the M.E.S. software will identify for short periods of time (days).

ICT’s & Artificial Intelligence

- First of all, you need the base, M.E.S. like Captor® (Sisteplant) performing the functions of

- Flow keeping around the assembly main line drummer.

- Traceability and quality keeping

- Production and assembly scheduling

- Crisscross back & forth alarms

- Second, a software for equipment and process predictive reliability, such as the CAMT Prisma® (Sisteplant). This piece of software is important given the intention of having a permanent synchronized flow around the final assembly in the dockyard, then practicing optimal predictive-preventive maintenance in the crucial machines (cranes, sheet-metal forming, welding and handling devices mainly).

- Third, once the former software of MES and CAMT have been practiced, they can be enhanced with A.I. In our case, Promind® (Sisteplant) gives out advanced analysis and recommendations around more precise prediction of alarms in quality, flow disruptions, and machines failures.

- Forth, the same Captor® can be used for optimal dynamic concurrent scheduling using it’s A.I. own techniques embedded in one of its modules.

- Fifth, integrate I.O.T with Captor and Prisma in order to keep followable along their entire life all the events concurring in the life of the parts and components that the ship incorporates.

Anyway, the most important thing is to define the business model the shipyard wants to perform, and then use all these physical, logical, and ICT technologies to enhance it, so increasing advantage over competitors in a well-established way.

THE MODEL

Always difficult to assess is the closing of leading shipyards in our western countries. Even understanding that several forces are pro & cons in the competitiveness, summary:

Cons: Traditional product: humans make ships from ever so it’s difficult to innovate in the more standard ones (cargo, porta-containers, tankers, …).

Cons: Ships are more tolerant than other constructions to quality defects, unless they are really flagrant and/or the vessel engages extreme weather conditions or strange aggressive events.

Cons: Labor intensive production unbalancing decisions to low-cost countries.

Pro: Intelligent thoughtful shipowners that think on all the ship-ownership and post life, know the difference on assumed risks, eco-commitment, and total operational costs between a poor details-quality built vessel and a careful designed, manufactured and assembled one.

Pro: At the core of almost any shipwrecking is always some direct mechanical early wear, or maintenance careless due the unlikely or intricated access for preventive actions. A clever design and selection of materials avoid the bug.

Pro: And so, almost any shipwrecking leads to spillages that heavily contaminates seas, with big moral, marine and human health, market, and economic consequences.

Pro: Critical quality on details require of deep crossed engineering and manufacturing squills that are only found in the western-style countries.

Cleverly unbalancing to PROS this balance makes the difference between competitive future shipyards and poor prone to closing ones.

So, naval construction with future in our western countries is very precise: ships with high technological added value in which are critical three factors:

- Arena for offering advanced functionality that is based on emerging technologies.

- Way in the critical difficult details are designed and built in.

- A limited % of steel working in the ship cost in favor of systems and equipment engineering integration.

The kind of where these factors may be more present are:

- Military and special operations

- Oceanographical and ecology

- Advanced eco-ships like “rotating sails” crafts

- Dredger and port-operation special ships

- Advanced fishing boats.

In all of them, engineering decisions are complex and critical all along, concurrent with manufacturing and erection from the keel laying to the launching and systems completion and testing.

Let’s having a vision over how these requirements impact the areas of design, manufacturing, supply chain, organizational issues and supporting ICT’s.

a. Product engineering (kits)

Key is here same own designed and tested “standard solutions” that improves the preliminary design the shipowner presents as specifications, and that are easy to “plug-in” on the overall project. This means to have an “own-product”, with all the synergy behind it.

The design areas must then be networked by an integrated system of:

- Standard own product development

- Technological support areas (e.g. naval architecture propulsion, hydraulics, seakeeping, electric-electronics, etc.).

- Virtual engineering project management cells that make design decisions to flow agility, rapidly driving the back & forth events to final stable points.

- Virtual view of the kits over process along the shipyard.

[vc_row][vc_column width=”2/3″][vc_single_image image=”9586″ img_size=”large” alignment=”center” style=”vc_box_rounded”][/vc_column][vc_column width=”1/3″][vc_column_text]

CYBER SHIPYARD LAY-OT CONCEPTUAL SCHEME

- Note the polyvalent lat-long launching docks.

- Note the cranes moving areas.

- Note the uncrossing flows in the workshops WS.

[/vc_column_text][/vc_column][/vc_row]

b. Manufacturing

[vc_row][vc_column width=”1/2″][vc_column_text]Synchronization and reliable forward steps with no return is the strategic key. A drone “bird view” of the shipyard assisted by a software of A.I. like Promind® can evaluate that in two

planes:

- A real time one for agile scheduling

- A batch one for manufacturing engineering changes in lay out, tooling, and handling configurations and equipment.

This last is important because not every lay out is appropriate for synchronization. So, its design must be specifically conceived for, and so drawn for:[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”9587″ img_size=”large” alignment=”center” style=”vc_box_rounded”][/vc_column][/vc_row]

- Synchronization, avoiding interferences crisscross of any flow of pieces that are heavy and voluminous, and so very slow to move.

- At least two water-front dockyards, square-angled, and supported by an also square lay-out to avoid flow interferences.

Doing well, the pieces to move will be bigger with time, because structure and systems completion will place in the up-flow dedicated workshops. This also facilitates flexible automation by kinds of robots, a very difficult thing once the piece is over the dockyard. This last is a place for rapid “plugging in” and not so much, what assures quality and repeatability, and hence seagoing ship reliability.

Note that this concept is entire synergic with the above idea of having “standard mode solutions” as a core part of the shipyard technology and differentiation.

Dockyard automation prime is to facilitate that laser-assisted “plugging-in” of hull sections along with other more secondary, as multipurpose special designed welding robots and simpler painting ones.

Other important mechanical items to support a high precision, and low-labor fabrication are:

- Flexible-adaptative tooling in sheet heating conform and blocks welding erection.

- Robotized piping manufacturing cells including cutting, bending and welding in tight-line

flow.

c. Supply chain. SMC

The key point here is to integrate suppliers into the ship erection process as any other internal manufacturing section, including working inside the shipyard. This requires long term loyal compromises, and not price negotiation in each project.

This model requires a common pool of ERP’s sharing information, along with dedicated project members engaged into the “back & forth” ICT supported interaction system.

The worst thing for quality and lead-time enlargement is building artificial physical, informative or administrative barriers inside suppliers and project steps. These barriers act as an obstacle for the fast, clear and concise data flow in the entire supply chain, affecting the overall efficiency and productivity.

d. Organizational Issues

The building of a complex system as a ship, with concurrent engineering decisions along, requires proactivity in people from the manufacturing process. Doing this well needs an advanced training level not only in their own job (welding, e.g.), but in the other proxy related as well, having an overall understanding of the whole process. So, the training for enough knowledge in the ship functionality and the challenges it poses to the shipyard, must be deep provided to by all the workers along.

Teamed in virtual dynamically mutating cells, people have to demonstrate contribution to the group, which makes this advanced training essential.

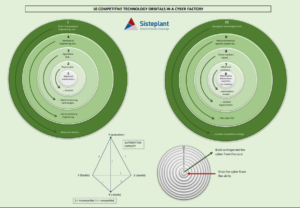

[vc_row][vc_column width=”1/2″][vc_single_image image=”9588″ img_size=”large” alignment=”center” style=”vc_box_rounded”][/vc_column][vc_column width=”1/2″][vc_column_text]e. Supporting ICT’s

Not any neutral ICT will provide competitive advantage. The key here is to built it around the defined own kitted product, and the manufacturing technological strategy reinforcing it, making so very difficult to emulate by others.

The modern cyber shipyards demand much more than CAD/CAE/CAM systems and shared ERP’s. The competitive reactive-proactive back & forth project management model calls for:

- Real time flow management and reconfiguration; a MES system (like Captor®).[/vc_column_text][/vc_column][/vc_row]

- Real time process quality and equipment reliability; a CAMT, Maintenance Management System (like Prisma®).

- Real time filtered decisions for predictive problems assessment in product/process imbricated issues; an A.I. based reliability management system RMS; (like Promind®).

- Real time deep interaction Man-Robot along the maintenance of process and equipment through a RIS, Robot Interaction System (like Profun®).

[vc_row][vc_column][vc_single_image image=”9589″ img_size=”full” alignment=”center” style=”vc_box_rounded”][/vc_column][/vc_row]

CONCLUDING REMARKS

Western shipyards need a deep business model transformation that goes from “building ships to deliver seagoing systems”. This concept is much more than a rhetorical intention; it demands a careful conceived and harmonic holistic product–process–organization and technology netting.

Urgency for doing so is in the edge, before more today profitable facilities fall in a spiral from which is then almost impossible to climb up.

The time and synergistic model that is lost when such a complex tech added–value activity finds economic difficulties is so big that not an effective return to competition will be possible.

[:]