Cyber factorys and the products they produce must go hand by hand, but not in a sense of superficial thinking as a “full intelligent” or sophisticated marriage.

The vintage 50’s – 60’s time mirroed in products its own values, many of them rooted in the assumed by-present danger of the cold-war mutual anhilation:

- Simple & reliable

- Elegance and good-taste

- Durable

- Priced made

- Delight eagerness with

Each product, whatever it was all about, deserved the expectation and a deep born desire of posession.

Today, the trivialization of consumption, the almost always excesive futile ICT product automation, and the culture of low-price use and trash items, has built a pleïad of stupid products candidates to recycling as fast as possible.

Factory-Intelligent Automation with practical human-rolled related limits, is another thing, and as the opposite we must evolve to use it as a vehicle to deliver more vintage-rooted products at an accesible price. And so, beginning to change customer culture.

So, guidelines for product development conception:

- Innovative for vintage tangible values

- A limit to incorporated software, if sense on

- Practical, simple, and comprehensive

- Durable, no-cheap

- Pure and transparent features (in food, e.g)

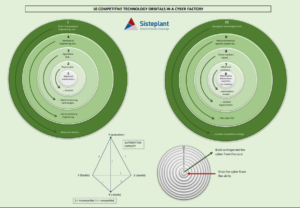

And the industrial practices evolve as follows, from the present “Design for manufacturing” (DFMA) to:

- Concept development from the classical “product-engineering”, details from evolved “process-engineering” = Automation Engineering + Quality Engineering + Maintenance Engineering FUSSION!!”

Feedback of Conceptualized details by “product-engineering” again.

- All it focus to “Design for Intelligent Automation” and “Design for product reliability” as high repeatable standards.

- Design cycle backgrounded on flow-increasing value along product development “virtual cells”.

From capital equipment goods, to durable consumer goods, to pharmaceuticals or food an opportunity for change dawns.