Being enthusiastic of pulse lines some years ago, thinking on improving aircrafts manufacturing lead-times and mimic automakers productivity, now I’m skeptical about. Even for the much more simple and less technological items such as cars are. I see two reasons for that:

- The first one is that the sophistication, concurrent customized design details and the extreme care to have on a product that does delicated activity (fly), overrun standardized practices. Otherwise, “the artisan personalized touch” necessary to warrant reliability, is in danger.

- The second is that the growing unstoppable customization around everything heads for the “one of a kind”, and that obviously puts more and bigger barriers to all the former.

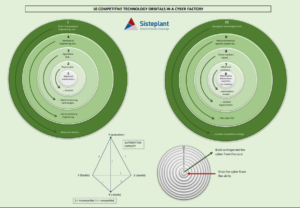

The X.0 by the scientifical way (see the fig) facilitates both.

Does it all mean that we have to remove any intention for jumping on manufacturing lay-outs from the actual “erection point”? Must we find stepping out from other fields?

No doubt that concurrent and permanent on line design is an area of deeping. Not only with the manufacturing or assembly operations, but with 6Sigma (no less than) reliability and maintainability.

Permanent interactive re-design has the danger of mess-heads, and finally risks to fall in unadverted errors, the most harmful of all them.

One possible way-out is to select the core, more stable part of the design, and select for it a short pulse line with no more than 2/3 steps (see figure), in order to avoid what happens when you try to standardize and divide the work among potentially more disconnected people.

This strategy leads to hold high Ksigmas. There, K=6/7 is the best warranty to prevent tolerances stack, the key factor avoiding reliability failures, and in high engineered products (HEP) such as aircrafts, also big efficiency and lead-times holes.

Note that in these one of kind customized HEPs, the Ksigma in the manufacturing processes hit straight the reliability of the final product, then the special efforts we have to put on them.

Being enthusiastic of pulse lines some years ago, thinking on improving aircrafts manufacturing lead-times and mimic automakers productivity, now I’m skeptical about. Even for the much more simple and less technological items such as cars are. I see two reasons for that:

- The first one is that the sophistication, concurrent customized design details and the extreme care to have on a product that does delicated activity (fly), overrun standardized practices. Otherwise, “the artisan personalized touch” necessary to warrant reliability, is in danger.

- The second is that the growing unstoppable customization around everything heads for the “one of a kind”, and that obviously puts more and bigger barriers to all the former.

The X.0 by the scientifical way (see the fig) facilitates both.

Does all it mean that we have to remove any intention for jumping on manufacturing lay-outs from the actual “erection point”? Must we find stepping out from other fields?

No doubt that concurrent and permanent on line design is an area of deeping. Not only with the manufacturing or assembly operations, but with 6Sigma (no less than) reliability and maintainability.

Permanent interactive re-design has the danger of mess-heads, and finally risks to fall in unadverted errors, the most harmful of all them.

One possible way-out is to select the core, more stable part of the design, and select for it a short pulse line with no more than 2/3 steps (see figure), in order to avoid what happens when you try to standardize and divide the work among potentially more disconnected people.

This strategy leads to hold high Ksigmas. There, is the best warranty to prevent tolerances stack, the key factor avoiding reliability failures, and in high engineered products (HEP) such as aircrafts, also big efficiency and lead-times holes.

Note that in these one of kind customized HEPs, the Ksigma in the manufacturing processes hit straight the reliability of the final product, then the special efforts we have to put on them.

The resulting lay-out must be equilibrated in terms of processing areas, that counts for focal-management-points in engineering and production concurrent operations. I would recommend a flow like the above figure, with no more than two or three pulsed steps and three erection sites per each lead line. This pounder conception allows to evenly distribute concurrent engineering efforts, and prevent the stack of tolerances, lead times, and inefficiency.

Note that 2 pulsed steps are the minimum, and removing one of them would probably give less Ksigmas and more lead time. If the product B.O.M. complexity recommends more than 2/3 of them, just set up feeding auxiliary lines, with less interfacing weight.

The argument for all the thing is that:

- If you reduce the synchronized pulsed-steps, will trip on vertical concurrent complexity, because of the unfeasibility to manage a long horizontal chain of facts. So, increasing the pulses, simplify this item.

- But each separated pulsed step adds interfacing with the previous and the next ones, and so horizontal concurrent complexity.

“Au fur et à mesure” that you progress in concurrent experience, will get more criteria to balance both terms, but at the beginning never create more than this threshold.

—————–

Author:

Javier Borda Elejabarrieta. Prof. Dr. Ing., President of Sisteplant.