Author:

Javier Borda Elejabarrieta. Prof. Dr. Eng., President of Sisteplant.

Yet old concept, it helped to upgrade organizational maintenance models introducing two bases:

- Self-maintenance

- OEE and its losses

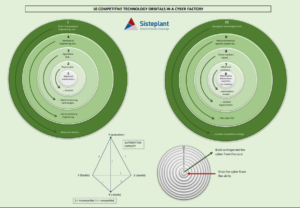

From there, in Sisteplant we have linked them to much more technological items that fit better in the 4.0 frame.

- Scientifical Maintenance Engineering deeply rooted in extended machine vibrations and their impact in 6Sigma manufacturing.

- Artificial Intelligence assisted RCM with Promind-Prisma, all of them the active heart of Maintenance and Process Technology.

- Deep knowledge transversality among product-process-quality-maintenance engineering, with active “tech-value-flow” passing through.

- Full empowered operator self-motivated by a radical comprehension of technology.

- Yet more by the assistance in maintenance of intelligent robots and the interactive software Profun-Captor.

- An extended OEE with losses ranged from the more scientifical-long term consistent effects (the true core) to the mere organizational ones.

- How to deal with continuously changing bottlenecks, given out by the agile re-flowing of an extremely small-lots flow.

- Traditional quality splitted in two parts: fail to reach ≥ 6Sigmas along the critical processes, and fail to rearrange flows in “near zero time”. So defects are not more an indicator of Q; the Sigmas that avoid or create them are instead.

We have defined a methodology (TIM Techno-i-Mant) that includes all them, and that classify the OEE extended losses as follows, taking by sure the organizational model fits TPM at least.