Author:

Javier Borda Elejabarrieta. Prof. Dr. Eng., President of Sisteplant.

“Permanent enormous opportunity for improvement”.

This is the conclusion of this paper. And now it’ll take feasibility from the I.T. and A.I. revolution.

This is very good news, because away from other manufacturing processes, engineering sophistication and it’s difficult to “close an early design”, materials management complexity, the happens of the unlikely, and the organizational and location spread of people, make E&C prone to differentiation.

Differentiation that is, obvious thresholds superated, based on the management of value through the details.

“A details focused company”.

Normally, if you (and it’s done almost always) engineer design details that rise value, they are progressively lost or misunderstood along the construction time and along the levels of hierarchy of the project. Differences and complaints arise once the construction is yet or almost finished, delaying due-dates and scaling costs.

One could think that this happens to every competitor always, from the beginning of the engineering big erections in the XIX s, and at the end nothing serious enough will remaind. And one could bet also that the I.T. revolution will help to fill the holes by it’s own insistive boring inertia.

NO. Reasons:

- People ramp-upped information and criteria

- Modern intelligent I.T. (mainly A.I. + I.O.T.) adds complexity over existing complexity, fixing chaos.

It needs to be modulated much more than ever, reportedly by its inherent power to order or disorder, this last leading to “everybody working for the system to run” instead of.

To ride of this dangerous scene, companies have to do as follows:

1) Include in the engineering design all the construction cycle details.

2) Identify on them “a priori”:

- Points of value and differentiation

- Detailed risk points

- “Do and undo’s”

- What ifs.

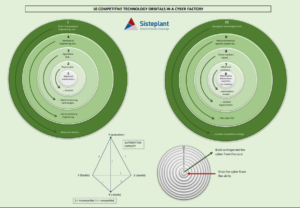

3) Articulate the flow of value along with special care at the interfaces, such as in the figure (imagined for a big aerospace project, but perfectly applicable to any erection in E&C):

4) Manage locally the value by mean of distributed “Aulas-Lab” in which the precise good-doing and badremoving are teached along with better practices.

5) Set the A.I. system supported in real time by M.E.S. and I.O.T.* to permanently perform a filtered events crisscross along the organization, making sure that the key people at all levels understand and interact.

6) This last means “permanent virtual real-time meets” based on incidences or preventive details made clear.

7) As an advanced step, complement the I.O.T. with the I.O.E. (internet of events) including here (maybe also electronically chipped) extended details and event notes.

Note that the keys 1), 2), 3) and 4) are strategy, not I.T., and that them drive this last represented by 5), 6) and 7).

We have in Spain a lot of big companies doing well along the world in the E&C sector. Let’s go to up-force that for a very big period.

∗ A.I. = Intelligent Interactive Engineering Decision Support system (f. i. Promind ®)

M:E.S. = Manufacturing Execution System (f.i. Captor ®)

I.O.T. = Internet Of Things (f.i. Smartions ®)